820 2121

"Our Focus your Finish"

820 2121

"Our Focus your Finish"

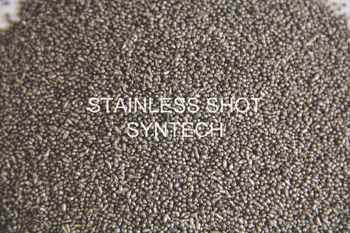

Stainless Chronital

CHRONITAL is used in all applications where non-rusting materials such as aluminum, zinc, stainless steel, brass, bronze, etc. are blasted.

CHRONITAL is used in all applications where non-rusting materials such as aluminum, zinc, stainless steel, brass, bronze, etc. are blasted.

CHRONITAL's large spectrum of grain sizes makes it well suited to cleaning, de-burring, hardening and surface finishing of all types of castings, forgings, profiles, wire and welded structural parts, without the possibility that rust could discolor the bright surface due to ferritic dust.

CHRONITAL distingishes itself by having a high percentage of spherical grains and by its compactness. The end result is low consumption, high performance and low machine wear.

Areas of Application:

- Blast cleaning, de-burring, surface refinement, surface finishing

- All types of Aluminum castings and forgings

- Zinc Pressure Die castings

- Non-ferrous metals and special alloys

- Stainless steel castings and forgings

- Stainless steel equipment fabrication

- Granite and stone industry

CHRONITAL offers the following advantages:

- Greater durability

- Shorter blasting times

- Brighter finish

- Rust-free surfaces

- Reduced wear on machines

Blsting of metal:

- for effective de-burring

- short blasting times

- perfect surface finish

- Rust-free surfaces

Cast stainless steel abrasive, rust-proof, spherical

Chemical Analysis: C - 0.17%, Cr - 18%, Ni - 10%, Si - 1.8%, Mn - 1.2%

Microstructure: Austenitic

Hardness:

Delivered - 300 HV (-30 HRC)

Work mix - 450 HV (-45 HRC)

Bulk density: - 4.7 g/cm3(-293lbs/ft3)

Packaging:

In convenient 25kg bags